solvtec ® IT System and Workflow Manager

solvtec ® IT SWM – Active project and process management (solvtec APQP)

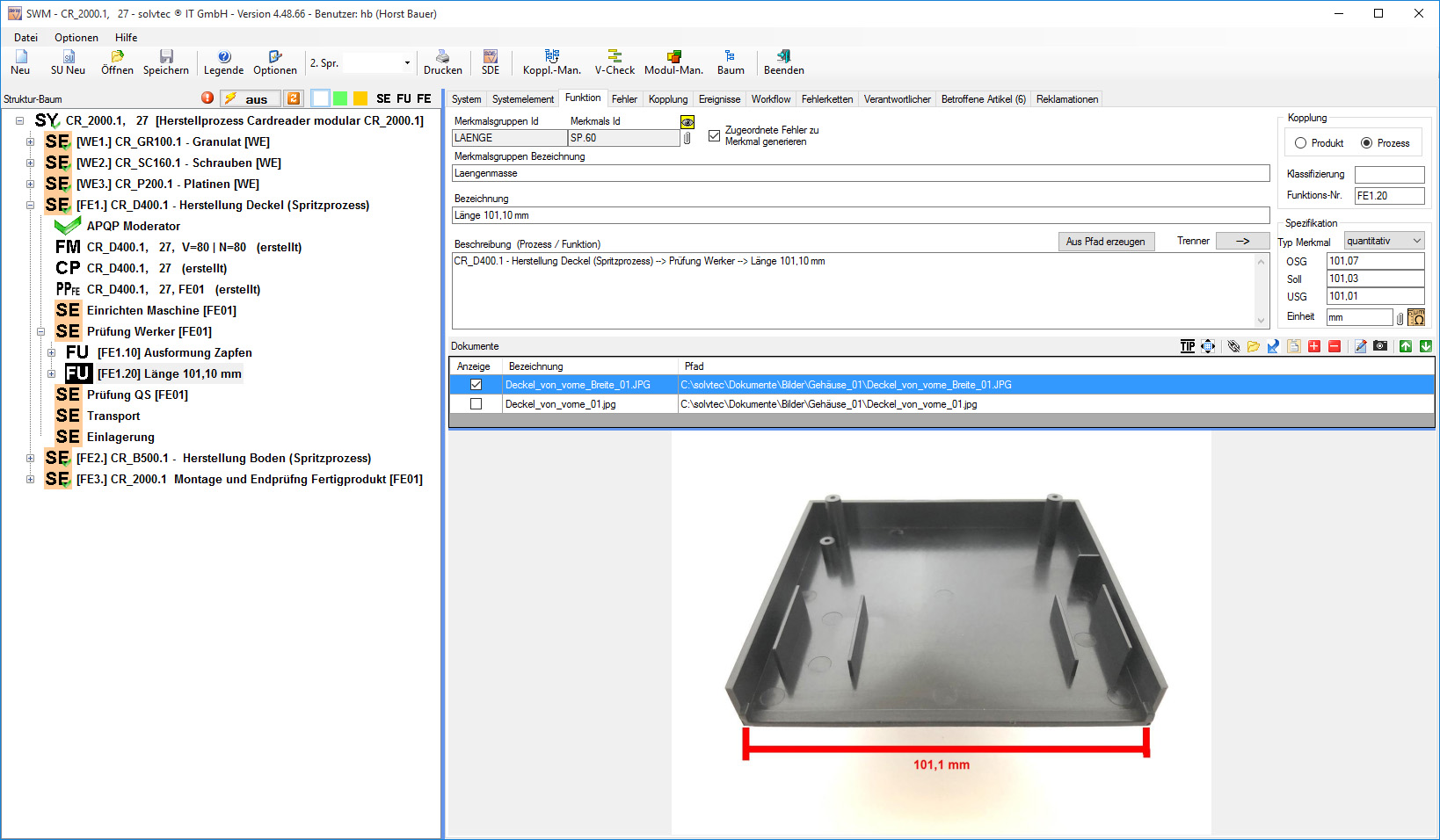

solvtec SWM gives you the ideal tool to change your APQP into an actively controlled process. SWM carries out the function of combining the relevant sub -processes into a single user interface. All relevant Q control circles are triggered from SWM by active relationships. APQP status lists and timing plans are generated automatically by SWM which helps optimize the process.

The active connection between SWM and Improvement Management (VBM) ensures that the Q control circles are complete throughout the company. Everyone involved is fully informed and the allocation of product or process versions is clear and explicitly defined. All relevant elements (FMEA, control plan, test plan, ISIR/PSW, audit etc.) can be controlled and are opened with a single mouse click.

Document and save approvals

The release of products or processes is documented and archived by solvtec ® IT SWM. Of course, all earlier versions remain accessible. It is thus possible to ascertain the effect of changes on running processes.

Administration of versions and security of their usage

The correlation of versions between FMEAs, control plans, test plans, and documents is performed simply, safely and transparently in the APQP workflow. All modules receive information and can be started from SWM. Usage of the correct version is thus universally ensured. Change management is actively supported.

Define workflows and control completion and time schedules

APQP workflows can be defined as standard and initiated with a mouse click. The elements (FMEAs, control plans, test plans, documents etc) can be actively interlinked and their status controlled. This saves considerable time and relieves some of the stress of those participating in the planning process.

SWM – FMEA – Control planning – Test planning

It is a fundamental principle of solvtec CAQ that information which is required at several places need only be maintained once in the system. This saves considerable time and effort and makes the life of all personnel involved in the planning process easier.

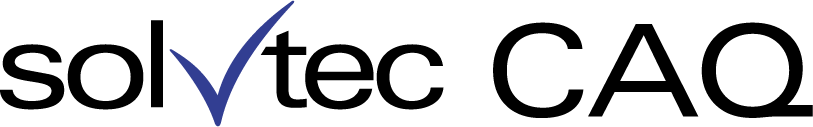

Structure, function and error analysis

A structure analysis can be performed by solvtec ® IT SWM as starting point for an FMEA. The product or process would be subdivided into individual logical elements or units. These elements can then be visualized and updated in clearly arranged tree or workflow diagrams. All details concerning the system elements, functions and errors can then be found here immediately.

Active support of FMEA, control plan and test plan – Up to 50% time saving

FMEA basic structures can be generated by mouse click using SWM. This allows those performing the FMEA to concentrate on the major issues, in particular process optimization. It is not necessary to repeatedly enter the same data into the system. Obviously, the same also applies to the generation of control plans and the resulting generation of test plans.

More impressions:

Discover Quality Management of the future

We will gladly advise you on all subjects connected to process and quality management. Try out our CAQ-software and see for yourself. Don’t hesitate to ask us. Simply tell us what you want!